EN

A software-defined vehicle (SDV) is one where key functions — like driver assistance, infotainment, and even core vehicle behavior — are enabled, controlled, and updated by software.

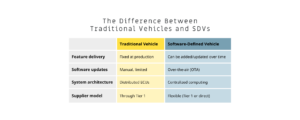

Unlike traditional cars, where most features are fixed at production, SDVs are built to evolve over time. New functionality can be added through software updates, and many systems are centralized into fewer, more powerful computing units.

This approach gives OEMs more flexibility, more control over the in-vehicle experience, and the ability to update and improve vehicles long after they leave the factory.

Software has played a growing role in vehicle development for years, but only recently have the tools, technologies, and expectations aligned to make software-defined vehicles a reality.

Today’s cars include more sensors, more connectivity, and far more computing power than they used to. Centralized vehicle platforms and over-the-air (OTA) updates have created the technical foundation for delivering new features through software.

At the same time, drivers expect more — from safety systems to digital interfaces — and OEMs want to differentiate their vehicles through software that can improve over time.

Software-defined vehicles are changing both how vehicles are designed and how the automotive supply chain is organized.

In traditional programs, software was often delivered as part of a larger system by Tier 1 suppliers. But as software becomes more central, some OEMs are choosing to work directly with specialized software providers on certain systems.

This doesn’t replace the traditional supply chain, but it adds more flexibility to it. In SDV programs, supplier roles can vary depending on the architecture and scope of the project.

For a broader look at how the automotive supply chain works, see our page on how the industry is structured.

In software-defined vehicle programs, it makes sense that software suppliers often take on a more central role. As a result, some OEMs choose to work directly with them as a Tier 1, especially when developing systems that require deep specialization.

For OEMs, it can provide quicker access to specialized expertise and more direct control over how certain in-vehicle systems are developed and maintained. For the software supplier, it deepens the collaboration and offers more visibility into the vehicle program, making it easier to tailor the solution to the OEM’s architecture and priorities.

At the same time, many continue to collaborate closely with Tier 1s as part of a larger integration. The structure varies from case to case, but the trend is clear: software expertise is playing a larger part in how vehicles are developed.